Tree of Life

Getting A Head

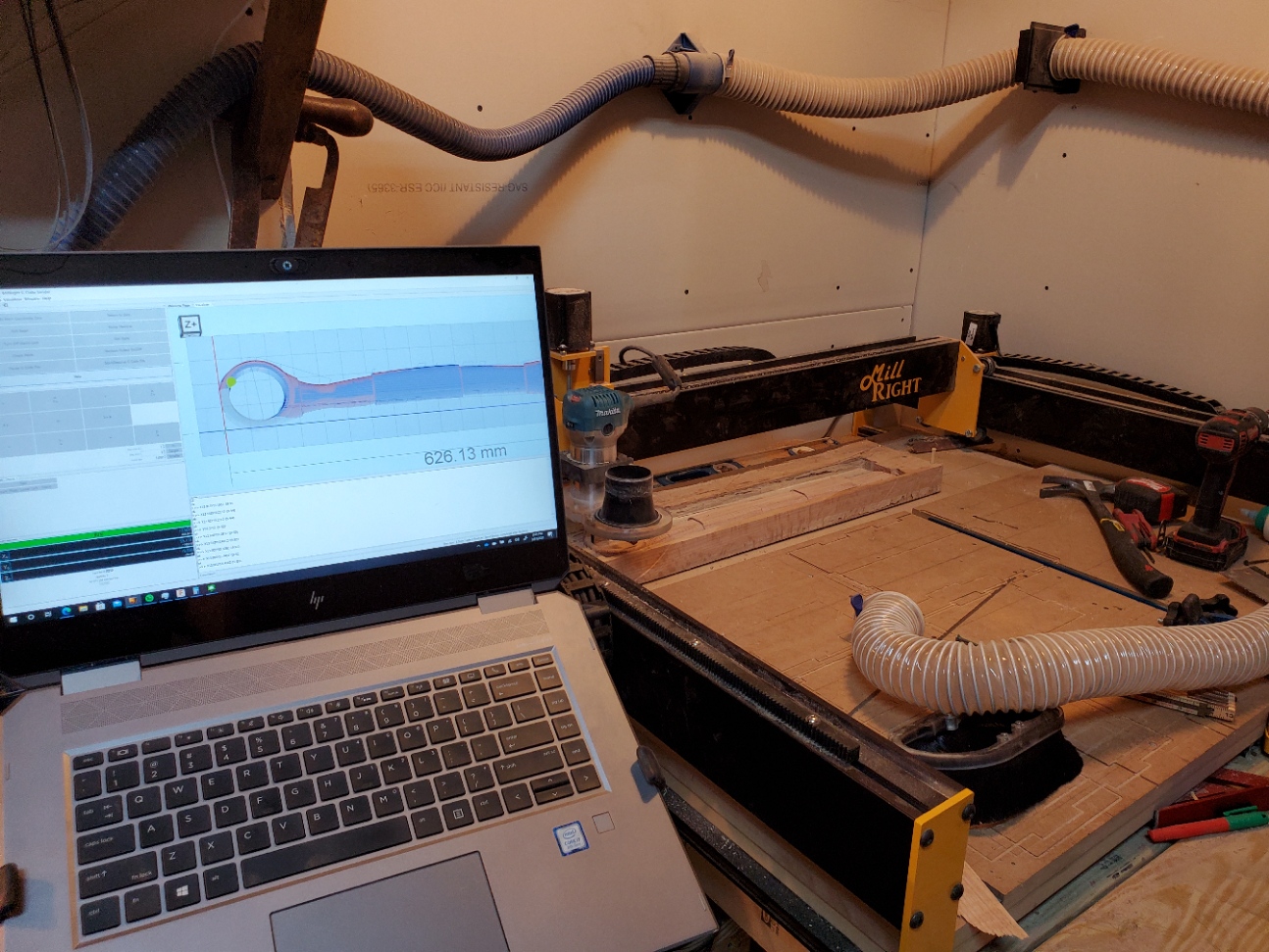

It’s been some quite time and even longer time getting the experience needed to elevate myself above novice, when it comes to utilizing a CNC Mill. I recently purchased a mill in January ’21 in order to make custom wood elements.

In life there are two things you can do, start small and work up or just go for Everest. I chose Everest. At first I thought it would be a relatively simple process to mill a 3-d object out of wood. If you have an actual 3-d model to work from yes, otherwise you have to create one from scratch. I’m no graphic artist. After a signification amount of research, I found that there is no better solution out there to work with than Fusion 360. There are numerous products out there but when it comes to support and forums, AutoCAD Fusion 360, dwarfs the competition.

Over the last few months I’ve been working to learn the ins-and-outs of Fusion 360, and after that began the process of trying to mill out my first axe handle. I’m not one to accept failure as my wife can attest, I’m no mathematician or anything like that but after countless failures, YouTube videos, pouring over blogs, forums, making alignment adjustments to the mill, you name it; I have a smidge of understanding what Edison felt like when he made the light bulb.

After nearly 3 solid months of failed attempts, I finally was able to complete an axe handle and therefore accomplish what I considered the mythical 2-sided milling. For many they would say oh its so easy you just use this or do that, but when trying to mill a non-symmetrical object, flip it over and mill the other side. Its far easier said than done.

One might wonder the reason for the “Tree of Life” reference in this post but also the handle itself. I chose it for a number of reasons. Ignoring the obvious, this handle stretched my patience significantly and after ruining a lot of wood blanks, finally from the ashes of defeat a single success sprouted up. This completed piece, represents that success at all levels. It is my hope that from this experience, this hobby might produce much fruit and excitement as I progress.

Design

27″ Seasoned Sweetgum handle

Carved sections for leather inlay

Sectioned Pommel for custom inlays

Fabrication

5 hrs – Handle Mill time

2 hrs – Pommel inlay Mill Time

1 hrs – Leather Wrapping

Finishing

2 hrs – Bison Leather 1/4″ inlay with all natural weather sealant, along with beeswax high gloss finish.

1 hr – Wood treatment with Tried & True Varnish oil.

Subscribe

Join our Monthly newsletter for sales & Updates